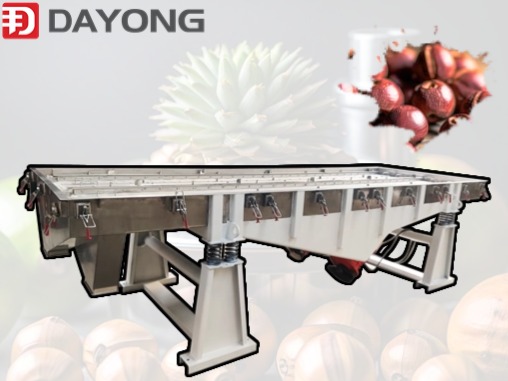

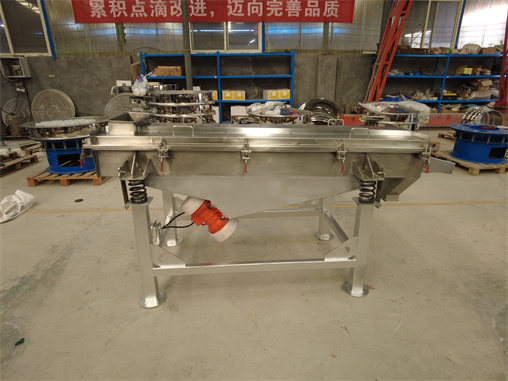

Industrial Mining Linear Vibrating Screen

The DY type linear vibrating screen produced by Dayong Equipment Co., Ltd. is driven by double vibration motors and uses the principle of vibration motor excitation. The product has high screening accuracy, large processing capacity, simple structure, good sealing performance, convenient maintenance, and can be used for automated operations in assembly line production. It is widely used in the screening of dry powder, fine granular or fine powder materials in abrasive raw materials, chemical industry, plastics, medicine, resin powder, ceramic raw materials, metallurgy, building materials, grain, food, fertilizer and other industries.

The DY type linear vibrating screen produced by Dayong Equipment Co., Ltd. is driven by double vibration motors and uses the principle of vibration motor excitation. The product has high screening accuracy, large processing capacity, simple structure, good sealing performance, convenient maintenance, and can be used for automated operations in assembly line production. It is widely used in the screening of dry powder, fine granular or fine powder materials in abrasive raw materials, chemical industry, plastics, medicine, resin powder, ceramic raw materials, metallurgy, building materials, grain, food, fertilizer and other industries.

Features: linear vibrating screen has the characteristics of high screening accuracy, simple structure, convenient maintenance, low energy consumption, low noise, good sealing, reducing dust pollution, and long screen life.

Use and maintenance:

1. When the screen machine is running, its vibrating part shall not be connected or contacted with any object outside the machine. (The soft connection cannot refer to vibrating screen, circular vibrating screen or high-frequency vibrating screen, and must be used under the guidance of the manufacturer)

2. When feeding the material, it should be fed in the width direction of the entire screen body at the feeding port to ensure the uniform distribution of the material on the screen surface.

3. When the material falls, there should be no big impact, so as not to damage the screen.

4. Before starting and stopping, there should be no remaining materials on the screen surface.

5. If there is any abnormal sound during the operation of the equipment, it should be shut down immediately for inspection, and can be turned on after troubleshooting.