High Efficiency Sieve Shaker Gold Mining Vibrating Screen Machine /ROTARY SIFTER/screen asphalt/sieve flour/sieves price/sieves vibro

Xinxiang Dayong Vibration Equipment Co., Ltd. produces and sells High Efficiency Sieve Shaker Gold Mining Vibrating Screen Machine /ROTARY SIFTER/screen asphalt/sieve flour/sieves price/sieves vibro is dedicated to sieving asphalt.A wide range of screening materials, no matter whether the material is dry or wet, fine or coarse, heavy or light, as long as the material is in the range of 0-400 mesh, it can be screened, even if the material is liquid or slurry, as long as the material is within 600 mesh. Also easily sieved.Oversize Material Outlet can also be called an oversize material chute which discharged the large ingredients after the sieving process is completed.

DY-600 Vibrating Screen /DY-800 Vibrating Screen/DY-1000 Vibrating Screen

Price:598$-898$

When the High Efficiency Sieve Shaker Gold Mining Vibrating Screen Machine /ROTARY SIFTER/screen asphalt/sieve flour/sieves price/sieves vibro starts to run, the operation of the vibrating motor produces an exciting force. Under the action of the exciting force, the machine body makes a compound movement, and the material on the screen makes a random body jump motion. It is also suitable for the screening of resins, coatings, industrial additives, cosmetics, coatings and other materials in the chemical industry, only the screen needs to be replaced.Equipped with a professional screen cleaning device, the screen will not be blocked in the process of screening materials, which greatly improves the screening output and screening efficiency of the screen.In order to further improve your material throughput, we offer optional unclogging systems that will “unclog” the sieve as it is used.

We offer two main cleaning techniques that have proven their effectiveness and robustness:

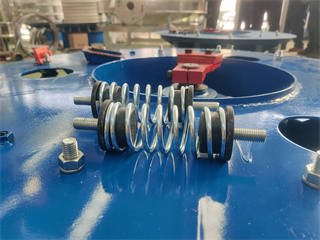

Ball cleaning: a system for cleaning the lower part of the screen cloth consisting of elastomer balls that bounce off a perforated stainless steel plate. This system is especially recommended in the event of the presence of fine products that can stick to the fabric threads.

Brush cleaning: a system where the brushes are located on the fabric. It is effective in certain very specific cases, such as when particularly sticky products or products that tend to clump together are used. This system is placed directly on the sieve and the rotation of the brushes is carried out thanks to the three-dimensional movements of the sifter.