High Efficiency Oscillating Linear Vibrating Sieve Screen For Kaolin /Linear Vibration Screen

High Efficiency Oscillating Linear Vibrating Sieve Screen For Kaolin /Linear Vibration Screen is produced and sold by Xinxiang Dayong Company and is specially used for the screening of lead powder in the chemical industry.

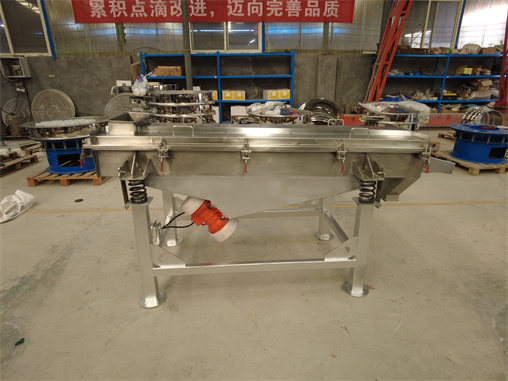

The multi-layer powder linear vibrating screen is driven by the double vibrating motor by using the exciting working principle of the vibrating motor. When the two motors rotate synchronously and in opposite directions, the eccentric blocks that generate vibration are offset from each other in the direction parallel to the motor shaft, and superimpose the resultant force in the direction perpendicular to the motor shaft, so the motion trajectory of the screen machine is a straight line .

High Efficiency Oscillating Linear Vibrating Sieve Screen For Kaolin /Linear Vibration Screen is produced and sold by Xinxiang Dayong Company and is specially used for the screening of lead powder in the chemical industry.

The multi-layer powder linear vibrating screen is driven by the double vibrating motor by using the exciting working principle of the vibrating motor. When the two motors rotate synchronously and in opposite directions, the eccentric blocks that generate vibration are offset from each other in the direction parallel to the motor shaft, and superimpose the resultant force in the direction perpendicular to the motor shaft, so the motion trajectory of the screen machine is a straight line .

When the two vibration motors vertically installed on the screen rotate relative to each other, the eccentric blocks of the two vibration motors generate rated exciting force. The horizontal exciting force cancels each other out, and the vertical exciting force is transmitted to the entire screen surface through the vibration of the body. Due to the action of the vertical exciting force, the material jumps on the screen surface towards the discharge port. The material smaller than the screen will fall into the lower layer after jumping and be discharged from the outlet. Due to the reasonable screening method, after passing through the vibrating screen, materials with different concentrations and different particle sizes can be obtained, and the materials can be classified.