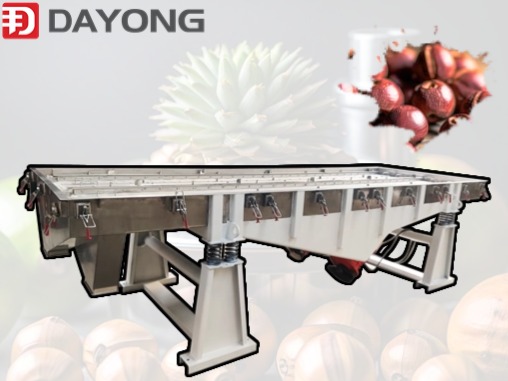

Herb Vibrating Separator/Rose Hip Seed Vibrator Separator/Vibrating Table For Gold Separator

Herb Vibrating Separator/Rose Hip Seed Vibrator Separator/Vibrating Table For Gold Separator produced and sold by Xinxiang Dayong vibration equipment Co., Ltd. is dedicated to screening rose seed gold.Bouncing ball cleaning: Food-grade rubber and silicone balls bounce on the punching plate under the screen, bouncing against the metal mesh to reduce mesh blockage. This system is simple to use, easy to maintain and suitable for most granular materials.

It is suitable for particle sieving, classification, impurity removal and filtration, with large processing capacity.

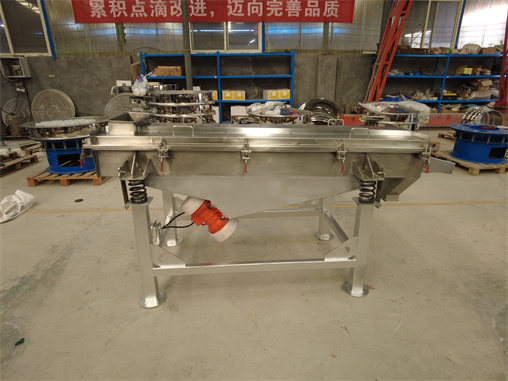

Material: stainless steel, carbon steel

Model: DZSF515, DZSF520, DZSF525, DZSF1020, DZSF1025, DZSF1030

Price: $1000-$1500

Herb Vibrating Separator/Rose Hip Seed Vibrator Separator/Vibrating Table For Gold Separator linear vibrating screen has high screening accuracy, large processing capacity, simple structure, low energy consumption, low noise, long service life of the screen, good sealing performance, very little dust spillage, convenient maintenance, and can be used for automated operations in assembly line production. This product is widely used in the screening of dry powder or granular materials in chemical, food, plastic, medicine, metallurgy, glass, building materials, grain, fertilizer, abrasive, ceramics and other industries. The product has high screening accuracy, large processing capacity, simple structure, low energy consumption, low noise, long service life of the screen, good sealing, little dust spillage, convenient maintenance, and can be used for automated operations in assembly line production.Turn on the power switch, confirm that the vibration motor rotates in the opposite direction synchronously, and run idly for 10-20 minutes. If there is any abnormal sound during operation, the equipment should be shut down quickly for inspection and processing. After the equipment is running normally, a small amount of material to be screened can be put into the screen machine through the feeding port, confirm that the material travels in the direction of the discharging port, and then gradually increase to the required and acceptable feeding amount.