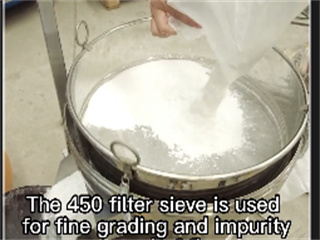

Gypsum Flour Vibrating Screen Supplier Sieve/rotary screening machine/screen vibrating machine/rotary screen supplie

Gypsum Flour Vibrating Screen Supplier Sieve/rotary screening machine/screen vibrating machine/rotary screen supplie produced and sold by Xinxiang Dayong Vibration Equipment Co., Ltd. sieve/rotary screening machine/sieving vibrating machine/rotary screen supplier is specialized in screening gypsum powder.The rotary vibrating screen is small in size, saves space, light in weight and easy to move. The exit direction can be changed at will.

At the same time, the rotary vibrating screen can be used for the screening of sugar, salt, alkali, monosodium glutamate, starch, milk powder, yeast powder, pollen, food additives, soy milk, fruit juice and other materials in the food industry. It is only necessary to replace the screen with the corresponding aperture. That’s it.

DY-600 Vibrating Screen /DY-800 Vibrating Screen/DY-1000 Vibrating Screen

Price:598$-898$

Gypsum Flour Vibrating Screen Supplier Sieve/rotary screening machine/screen vibrating machine/rotary screen supplie This machine is manufactured with imported technology. The rubber shock absorber is used to replace the traditional domestic metal spring, and the internal and external contact raw materials are stainless steel. It is an ideal equipment for screening and inspection of granules, slurries, powders and other materials. Suitable for pharmaceutical, food, chemical and other industries. In particular, it meets the requirements of G.M.P, so that customers can rest assured.The circular vibrating screen of Xinxiang Dayong Company has high screening accuracy and high working efficiency, and is suitable for any particle, powder and slurry.

It only takes 3 to 5 minutes to replace the corresponding size screen. In order to improve the screening effect of the rotary vibrating screen when screening fine materials, ultrasonic systems and other equipment can be added.

The grid of the rotary vibrating screen will not be blocked, it can be screened to 500 mesh or 0.028mm, and the coarse waste of impurities can be automatically discharged. Can work continuously.

It only takes 3-5 minutes to change the screen by rotating the vibrating screen. Small size, easy to operate. The screen machine has five layers at most, and it is recommended to use three layers more. At the same time, the number of layers can also be selected according to the material to be screened. ROTARY SIFTER/STAINLESS STEEL MESH/vibration analyzer/beans sieving machine/vibro sieve/vibro separator/stainless steel Vibrating dewater deoil machine /Flour Vibrating Sieve Machine/Vibro Separator Machine/fruit juice vibrating separator machine/flour sifter for bakery/sifter for flour/sifter flour sieve/flour sieve/china vibrating screen/bergetar classifiermachine /vibrate classifier/Vibratory Separator/Rotary Vibrating Screen/Vibrating Sieve/powder sieving machine/vibrating screen specification/vibrating sieves separator machine/vibration screening machine/circular vibrating screen/vibrating screen price/vibration screen frame/small sieving machine/ultrasonic classifying vibrating sieve/ultrasonic vibrating sieve/vibrate screen classifier/bergetar classifier/vibrating sifter waste/fabrication machine vibrating sieve/circular vibrating sifter/vibrate classifier/electronic industry sieve /flour sieve industrial/black soldier fly farming vibrating sieve separator/vibro screen machine/vibrating sieve separator/vibro screen separator/flour sieve/flour sifter machine/food grade pollen screen/electric sieve vibrator/rotary screening machine/screen vibrating machine/vibrating sieve for grain/food grade stainless steel screen/wheat mill sieve/gyratory sifter/sc/vibro sifter machine/direct discharge sifter /circular vibrating sifter/diamond sieve shaker machine/flour rotary vibrating screen/grinding sieving machine