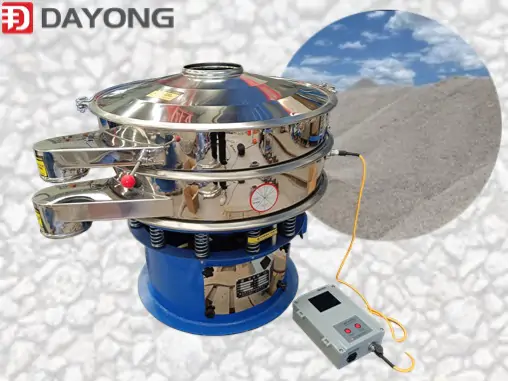

Graphite Sifter/Industrial Graphite Powder Filtration Centrifuge/Rotary Vibrating Screen For Graphite

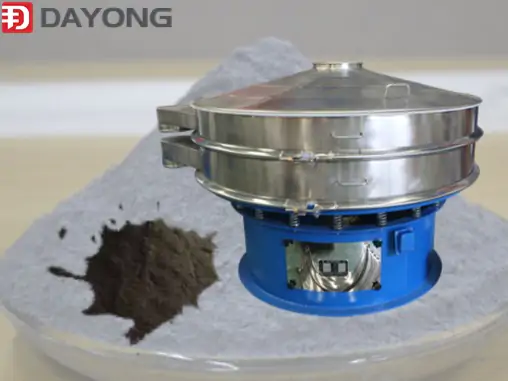

According to the characteristics of graphite powder, it is easy to generate static electricity problems, and of course, the filtration of carbon liquid and graphite slurry. Dayong Vibration Equipment Company recommends that you use an ultrasonic vibrating screen.

Ordinary vibrating screen is not easy to solve the problem of static electricity, but ultrasonic vibrating screen can meet various conditions for screening graphite powder, with high screening efficiency, and the screening process is clean and hygienic.

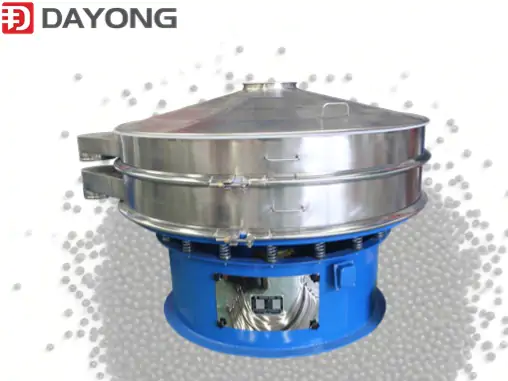

Ultrasonic vibrating screen is mainly composed of dust cover, upper frame, bottom frame, ultrasonic device, vibrating body, vibration damping spring, base, foot and other parts. On the basis of ordinary vibrating screen, a set of ultrasonic device is added, and the unique ultrasonic cleaning device can effectively prevent the phenomenon of screen clogging, and effectively solve the problem of strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity. It is suitable for the screening operation of graphite powder. Thereby inhibiting the blocking factors such as adhesion, friction, leveling and wedging.

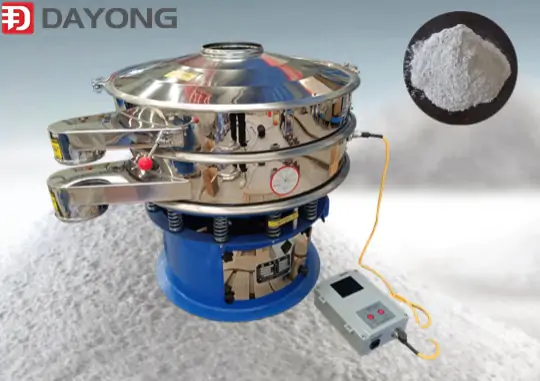

According to the characteristics of graphite powder, it is easy to generate static electricity problems, and of course, the filtration of carbon liquid and graphite slurry. Dayong Vibration Equipment Company recommends that you use an Graphite Sifter/Industrial Graphite Powder Filtration Centrifuge/Rotary Vibrating Screen For Graphite

Ordinary vibrating screen is not easy to solve the problem of static electricity, but ultrasonic vibrating screen can meet various conditions for screening graphite powder, with high screening efficiency, and the screening process is clean and hygienic.

Ultrasonic vibrating screen is mainly composed of dust cover, upper frame, bottom frame, ultrasonic device, vibrating body, vibration damping spring, base, foot and other parts. On the basis of ordinary vibrating screen, a set of ultrasonic device is added, and the unique ultrasonic cleaning device can effectively prevent the phenomenon of screen clogging, and effectively solve the problem of strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity. It is suitable for the screening operation of graphite powder. Thereby inhibiting the blocking factors such as adhesion, friction, leveling and wedging.

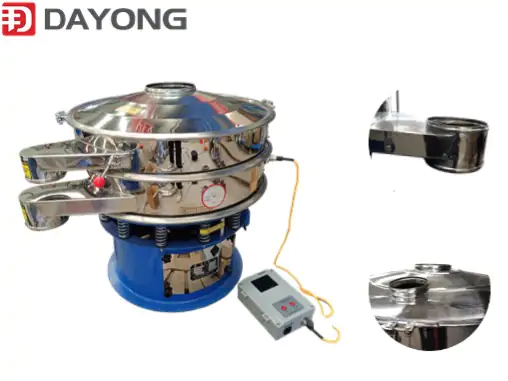

The advantages of using ultrasonic vibrating screen for graphite powder screening

1. Ultrasonic vibrating screen has high screening accuracy and meets special requirements such as precision screening. Under the premise of not changing the material characteristics, the screening accuracy can be effectively guaranteed. The installed ultrasonic screening system also has a net cleaning device.

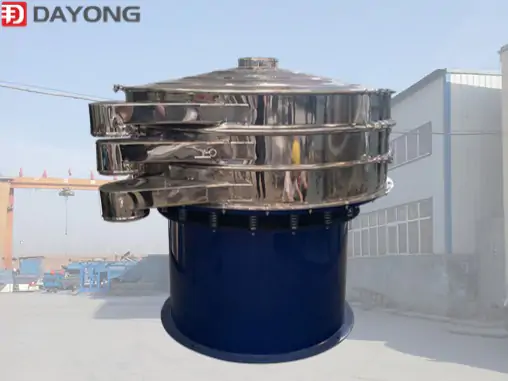

2. Large output and many models to meet the requirements of large output classification

Ultrasonic vibrating screen models are divided into eight standard models (DY-400, DY-600, DY-800, DY-1000, DY-1200, DY-1500, DY-1800), which can be installed with 3-layer screens, which can meet the needs of customers. Different screening yields.

If you have any questions, please contact us, the professionals of Dayong Vibration Equipment Company will answer your questions, customize the screening plan for you, and look forward to your reply.