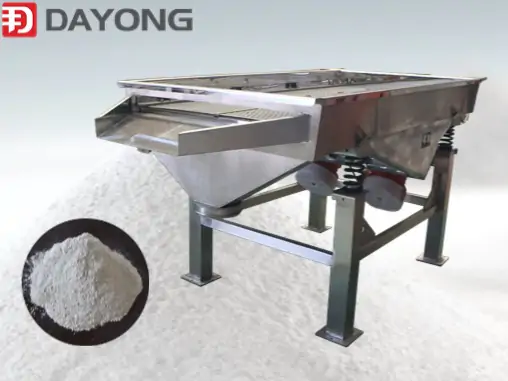

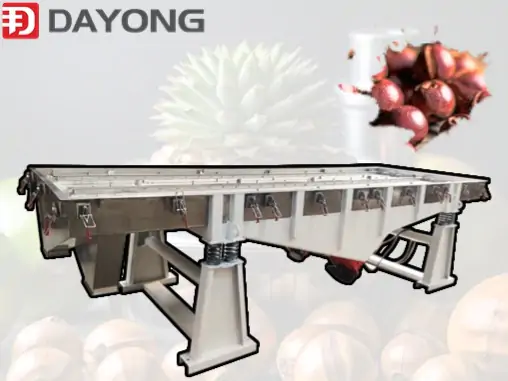

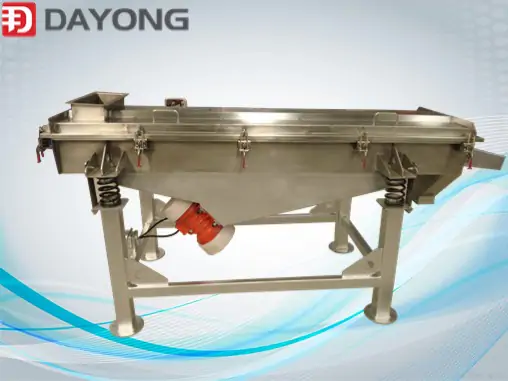

Granule Linear Vibrating Screen Pellet Flour Sieve Machine 3 Way /Linear Vibrating Grizzly Screen Separator

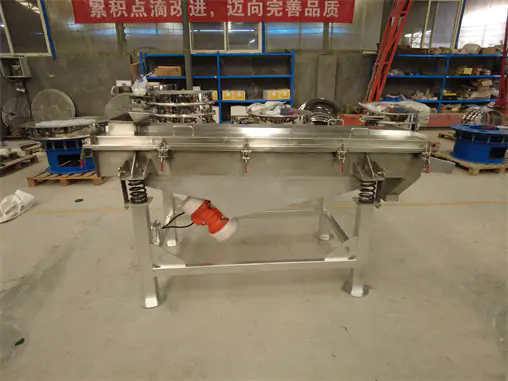

Xinxiang Dayong company has focused on the manufacturing of screening and conveying equipment for 11 years. Xinxiang Dayong company produces and sells Granule Linear Vibrating Screen Pellet Flour Sieve Machine 3 Way /Linear Vibrating Grizzly Screen Separator , which has a wide range of applications and is dedicated to screening particle flour.On the screen body and the upper and lower spring seats of the machine base, the springs should be completely embedded in the spring seats to ensure the balance of the screen body. The vibration part of the screen machine should not be rigidly connected or contacted with other objects outside the machine.

DZSF515,DZSF520,DZSF525,DZSF1020, DZSF1025 ,DZSF1030

Price:$1000-$1500

Granule Linear Vibrating Screen Pellet Flour Sieve Machine 3 Way /Linear Vibrating Grizzly Screen Separator motor is used as the power source; the material is thrown up on the screen while moving forward in a straight line, which can be matched with a single-layer or multi-layer screen to achieve the purpose of dehydration, impurity removal, inspection, etc.; it has the functions of grading and conveying. The product has high screening accuracy, large processing capacity, simple structure, low energy consumption, low noise, long service life of the screen, good sealing performance, little dust spillage, convenient maintenance, and can be used for automated operations in assembly line production. It is suitable for screening various dry powder materials with particle size of 0.074-5mm, moisture content less than 70%, and no stickiness. The feeding particle size is not more than 10mm.Linear vibrating screen is used for fine powder screening, especially suitable for difficult materials. If there is any abnormal sound during operation, the equipment should be shut down quickly for inspection and processing. After the equipment is running normally, a small amount of material to be screened can be put into the screen machine through the feeding port, confirm that the material travels in the direction of the discharging port, and then gradually increase to the required and acceptable feeding amount.