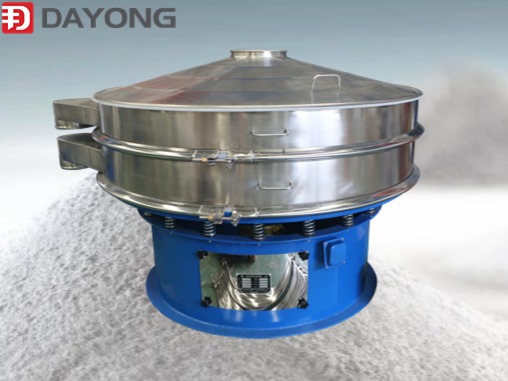

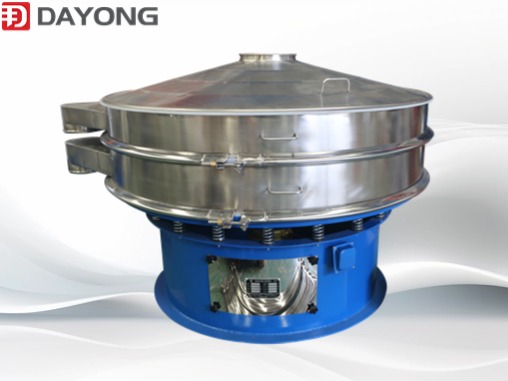

Grain Ultrasonic Grading Rotary Vibrating Sieve

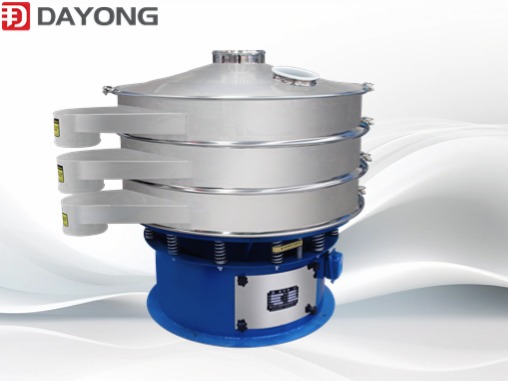

In the agricultural production process, a screening device is often required to screen agricultural crops. In the existing filter screening device, the crops are usually poured at one time during the use process, so that the crops are piled up and the materials above It is difficult to be screened. In order to overcome the above technical problems, Dayong Vibration Equipment Co., Ltd. provides an agricultural screening machine. The basic principle is to install a center of gravity hammer on the upper and lower ends of the equipment motor. This movement is transmitted to the mesh surface to achieve the purpose of screening. At the same time, changing the phase angle of the upper and lower weights of the motor can change the movement direction of the raw materials. Different movement directions produce different screening effects and different main purposes, including Rough grading, general sieving, precision grading, special purpose, etc. Meet different purposes of crop screening.

In the agricultural production process, a screening device is often required to screen agricultural crops. In the existing filter screening device, the crops are usually poured at one time during the use process, so that the crops are piled up and the materials above It is difficult to be screened. In order to overcome the above technical problems, Dayong Vibration Equipment Co., Ltd. provides an agricultural screening machine. The basic principle is to install a center of gravity hammer on the upper and lower ends of the equipment motor. This movement is transmitted to the mesh surface to achieve the purpose of screening. At the same time, changing the phase angle of the upper and lower weights of the motor can change the movement direction of the raw materials. Different movement directions produce different screening effects and different main purposes, including Rough grading, general sieving, precision grading, special purpose, etc. Meet different purposes of crop screening.

Why choose ultrasonic vibrating screen?

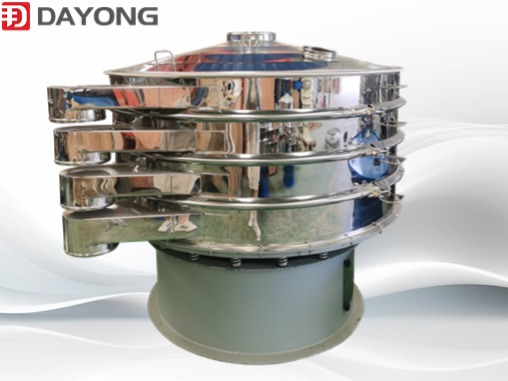

1. High screening accuracy, meeting the needs of fine screening and classification

Under the premise of not changing the material characteristics, the screening accuracy can be effectively guaranteed. With the ultrasonic screening system installed, it has the function of cleaning the screen itself, no need to add other screen cleaning devices, and the screening accuracy is high.

2. Large output and many models to meet the requirements of large output classification

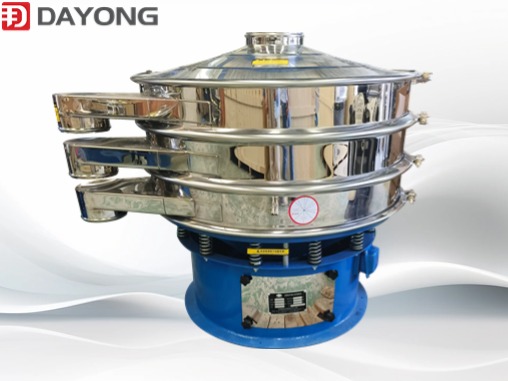

Ultrasonic vibrating screen models are divided into eight standard models (DY-400, DY-600, DY-800, DY-1000, DY-1200, DY-1500, DY-1800), which can be installed with 3-layer screens, which can meet the needs of customers. Different screening yields.

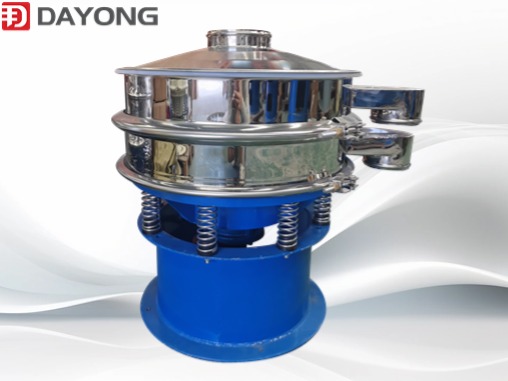

3. Screening is clean and hygienic, meeting food hygiene standards

The ultrasonic vibrating screen adopts a fully enclosed structure. The surface of the 304 stainless steel after internal and external polishing is smooth and free of burrs. The seals between the screen frames are all made of silicone material, which fully meets the food hygiene standards.