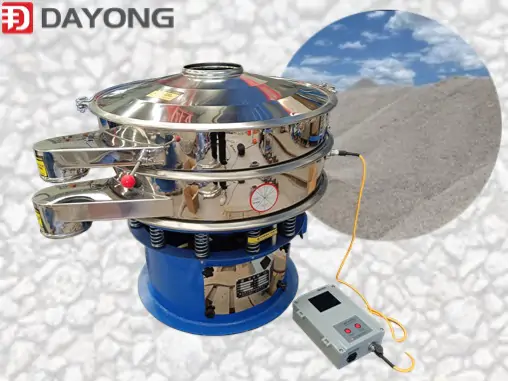

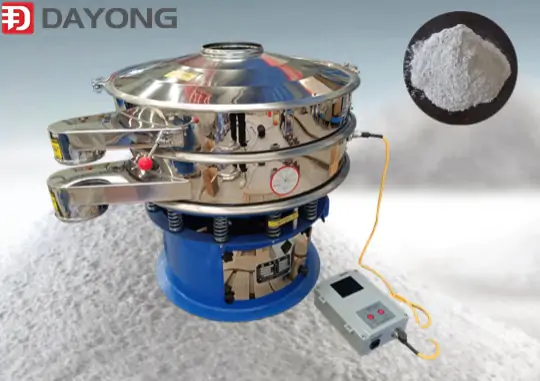

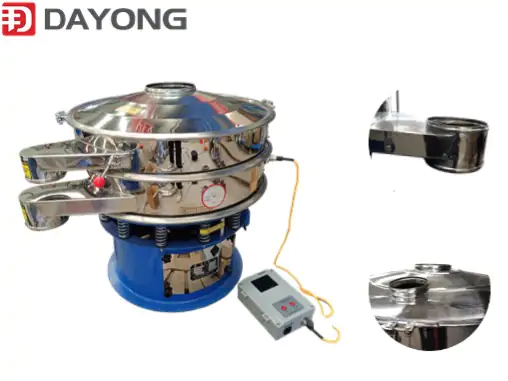

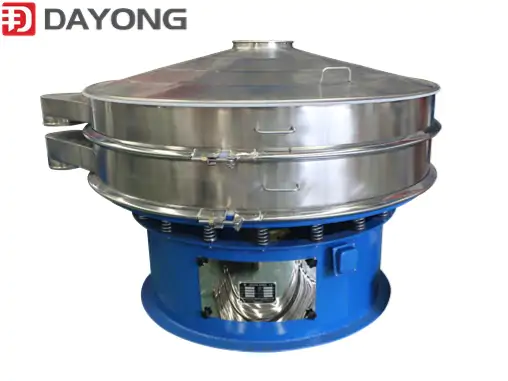

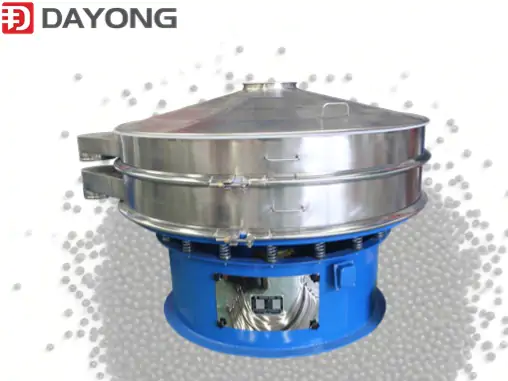

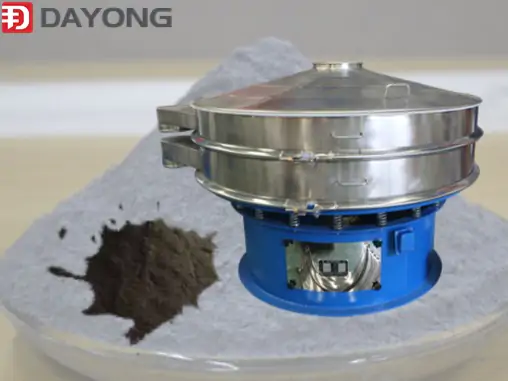

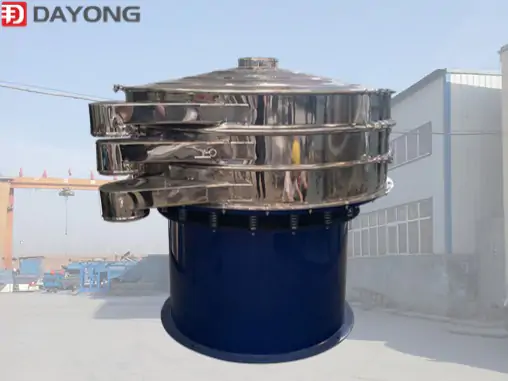

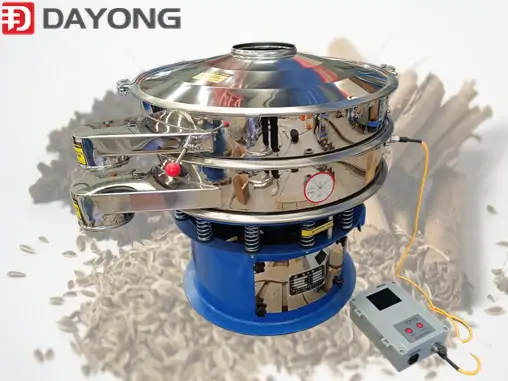

Grain Ultrasonic Grading Rotary Vibrating Sieve

Grain grading rotary vibration screening machine uses a vertical motor as the excitation source, and eccentric weights are installed at the upper and lower ends of the motor, which converts the rotary motion of the motor into three-dimensional motion of horizontal, vertical and inclined, and then transmits this motion to the The screen surface makes the material expand involute motion on the screen surface, so this series of vibrating screens are called rotary vibrating screens. The rotary vibrating screen produced by Dayong Vibration Equipment Company has the advantages of long material running trajectory and high utilization rate of screen surface. Adjusting the phase angle of the upper and lower ends of the weights can change the movement trajectory of the material on the screen surface. Perform fine screening, probability screening, etc.

In the agricultural production process, a screening device is often required to screen agricultural crops. At present, the more common screening devices include vibrating screen, rotary centrifugal and filtering type, etc. The existing filtering screening device, In the process of use, the crops are usually poured at one time, which makes the crops pile up, and the materials above are difficult to be screened, and the crops that are screened during screening are difficult to be completely discharged when they are discharged. In addition, the existing filter type The screening device screens a single material object, so an agricultural screening machine is proposed to solve this problem.

Grain grading vibratory screening separator machine uses a vertical motor as the excitation source, and eccentric weights are installed at the upper and lower ends of the motor, which converts the rotary motion of the motor into three-dimensional motion of horizontal, vertical and inclined, and then transmits this motion to the The screen surface makes the material expand involute motion on the screen surface, so this series of vibrating screens are called rotary vibrating screens. Rotary vibrating screen has the advantages of long trajectory of material running and high utilization rate of screen surface. Adjusting the phase angle of the upper and lower ends of the weights can change the movement trajectory of the material on the screen surface. It can perform fine screening and probability screening of materials. grade.