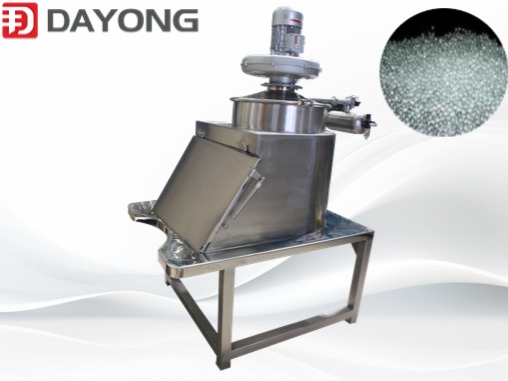

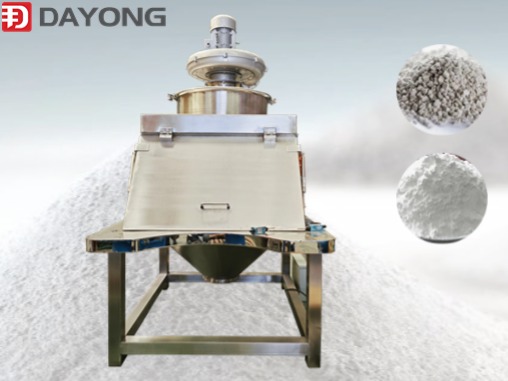

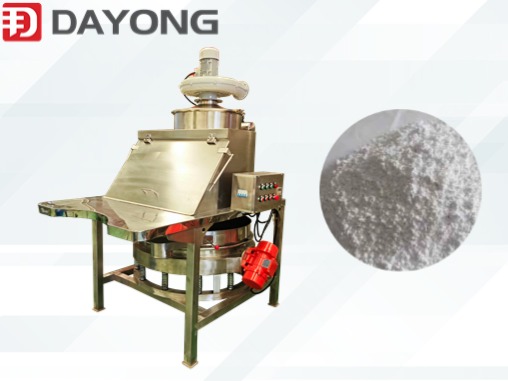

Glass bead feeding equipment – dust-free feeding station

The small particle size and easy pollution characteristics of glass microspheres pose extremely high requirements for the feeding process. Xinxiang Dayong Vibration Equipment Co., Ltd. will explain the application of dust-free feeding stations in this article.

There is a photoelectric material production enterprise that requires a large amount of glass microbeads as fillers when producing high transmittance reflective films. The enterprise has introduced a stainless steel dust-free feeding station produced by Xinxiang Dayong Vibration Equipment Co., Ltd., successfully solving the problem of glass microbeads being easily contaminated in traditional feeding methods. In this article, Xinxiang Dayong Machinery will introduce the application advantages of dust-free feeders in conveying glass microspheres.

- Clean production environment: The dust-free feeding machine effectively isolates dust, particles, and impurities from the external air through dust removal fans and sealing design.

- Improve production efficiency: The dust-free feeding station is easy and fast to operate, significantly improving production efficiency.

- Reduce material loss: The dust removal fan can blow back to minimize the loss of glass microspheres during the feeding process. Reduced production costs for enterprises.

- Improved working conditions: reduced dust spillage, improved the comfort and safety of the working environment.

- Easy to maintain and upgrade: The device has a simple structure and is easy to maintain and clean.

The application of dust-free feeding stations in glass bead feeding not only significantly improves the cleanliness of the production environment, but also effectively ensures the quality of products. Xinxiang Dayong Vibration Equipment Co., Ltd. is a manufacturer specializing in the production of vibration equipment and feeding equipment. If you have any questions, please feel free to contact us for consultation!