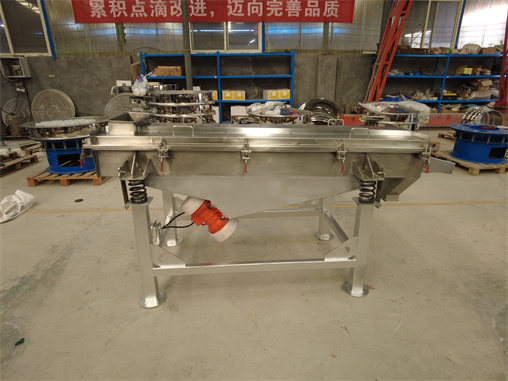

Factory Supply 1020 Stainless Steel Linear Vibrator Sieve Machine For Chrome Powder

The basic principle of the linear screen is that the efficient linear vibrating screen is driven by two vibrating motors. When the two motors rotate synchronously and reversely, under the influence of the resultant force of the exciting force, the exciting force generated by the eccentric block is parallel to the direction of the motor axis and is eliminated relative to the sieve plate. The self weight of the iron powder is thrown up, and the iron powder is sieved and graded by jumping straight on the sieve plate. It is applied to the pipeline to realize automatic operation.

The linear screen is equipped with two vibrating motors which rotate in reverse direction at the same time. The screen box is supported by four springs, which produce reciprocating linear motion under the action of the vibration force generated by the motor. When the vertical component of the vibration acceleration is greater than the gravity acceleration, the materials in the tank are thrown up and jump forward along a parabolic path. Every time the tank is vibrated, the material will be thrown out once. In the process of encountering the screen, materials smaller than the screen can pass through the screen to achieve the goal of classification.