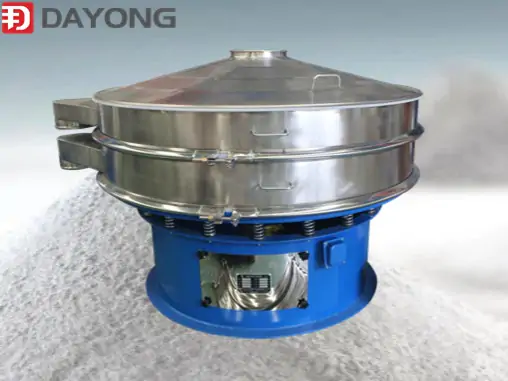

Factory Price Rotary Vibrating Screen /grain Vibration Screening For 10/40/80/100 Mesh Size

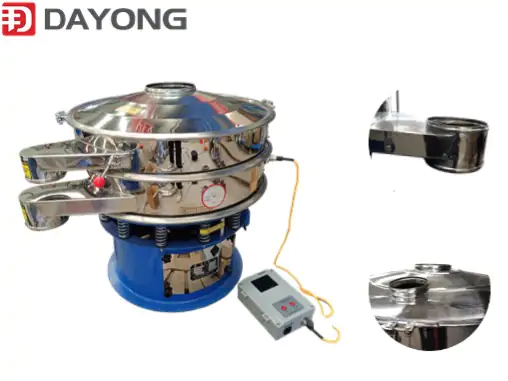

The Factory Price Rotary Vibrating Screen /grain Vibration Screening For 10/40/80/100 Mesh Size produced by Xinxiang Dayong Vibration Equipment Co., Ltd. can be divided into one-layer, two-layer, three-layer and four-layer type rotary screen according to the specific needs of screening materials. According to the different needs of users, it can be divided into standard rotary vibrating screen, ultrasonic vibrating screen, edged rotary vibrating screen, gate type rotary vibrating screen, etc. The materials are mostly stainless steel and carbon steel. According to the different applicable industries, it can be divided into flour screen, powder metallurgy vibrating screen, medicine vibrating screen and so on.

The Factory Price Rotary Vibrating Screen /grain Vibration Screening For 10/40/80/100 Mesh Size produced by Xinxiang Dayong Vibration Equipment Co., Ltd. can be divided into one-layer, two-layer, three-layer and four-layer type rotary screen according to the specific needs of screening materials. According to the different needs of users, it can be divided into standard rotary vibrating screen, ultrasonic vibrating screen, edged rotary vibrating screen, gate type rotary vibrating screen, etc. The materials are mostly stainless steel and carbon steel. According to the different applicable industries, it can be divided into flour screen, powder metallurgy vibrating screen, medicine vibrating screen and so on.

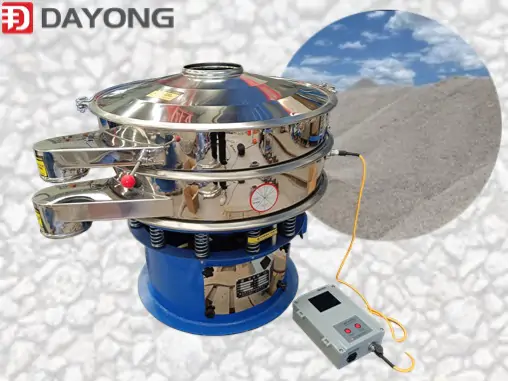

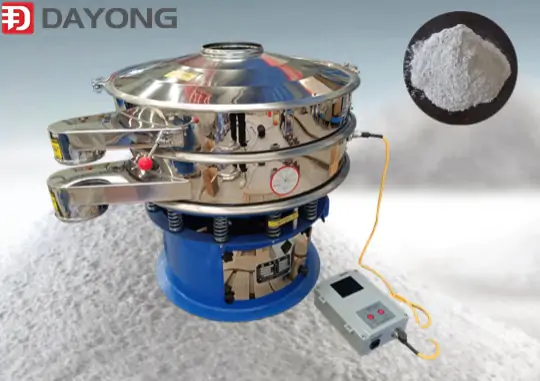

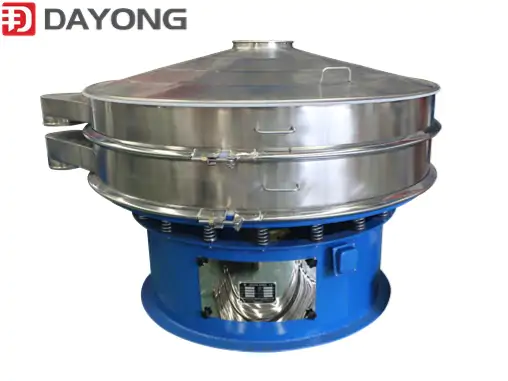

The dedicated vertical vibration motor is the excitation source, without mechanical transmission, with high energy efficiency, easy adjustment, reliable quality and high stability.

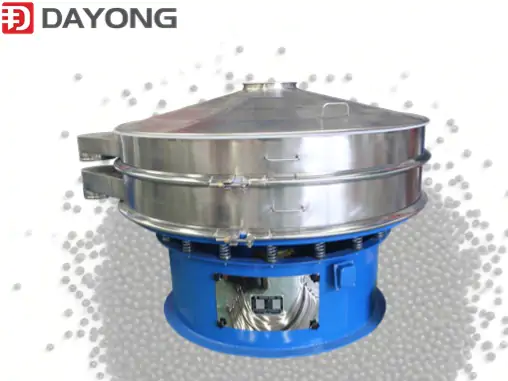

High screening accuracy and high efficiency, suitable for screening and filtering various powders, granules, mucus and other materials.

The design is exquisite and durable, with low noise, continuous operation, and the material can be automatically discharged in 360-degree direction.

The sieve has a long service life and is easy to replace. The specifications can be configured arbitrarily.

The whole machine has good sealing performance, powder does not fly, and liquid does not leak, and can be used in single and multi-layer at the same time, up to 5 layers;

The structure of the components has no dead ends, and it is easy to disassemble and assemble, and it is easy to be thoroughly cleaned and disinfected.