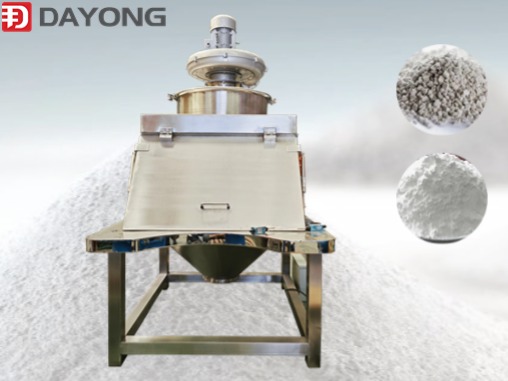

Dust free feeding station reduces workshop dust

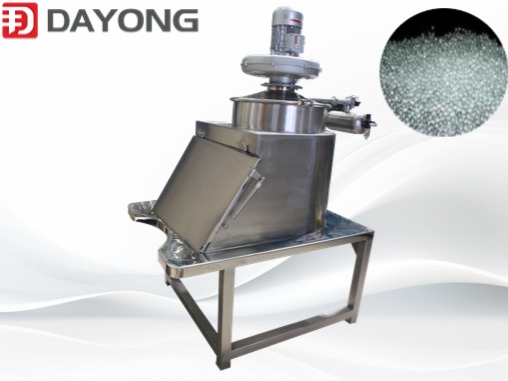

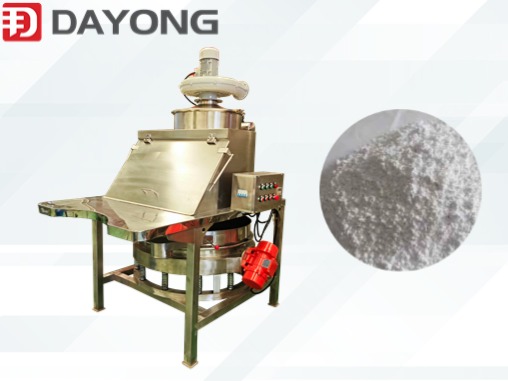

The dust-free feeding station can effectively solve the problem of dust flying in the workshop.The direct discharge screen is installed below the dust-free feeding station, with fast discharge speed and high processing capacity. The combination of dust-free feeding station and direct screening is the choice of most customers.

Recently, a customer who produces powdered materials approached us.The client is in the food industry and has high requirements for hygiene environment.Previously, the powder would fly to every corner of the workshop.This production environment is not up to standard for them.We recommended a dust-free feeding station for him.It can effectively solve the problem of dust flying in the workshop.

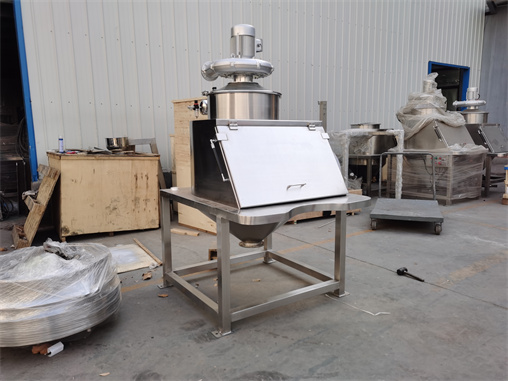

The dust-free feeding station is more suitable for unloading small bags of powdered materials by manually unpacking the bags and placing them into the hopper.The operator places the material bag on the bracket and pushes it into the grid.Next, the operator cuts a vertical opening in the material bag and shakes it to empty it.The material will fall into the hopper by gravity.

The equipment is equipped with a vacuum cleaner and a blowback device.Vacuum cleaners prevent dust from spreading.The blowback device avoids material waste.It enables employees to work in a clean environment, ensuring their health.In addition, the dust-free feeding station is entirely made of stainless steel material to prevent material contamination.

In addition, the customer also has a screening requirement.The height of the straight screening machine is low, making it convenient for on-site layout.It is installed below the dust-free feeding station, with fast discharge speed and high processing capacity.The combination of dust-free feeding station and direct screening is the choice of most customers.

If you have any further needs, please feel free to contact us at any time!