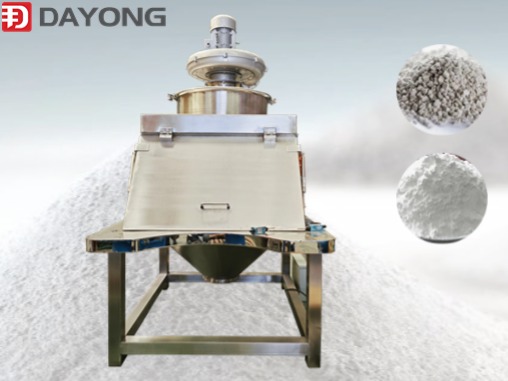

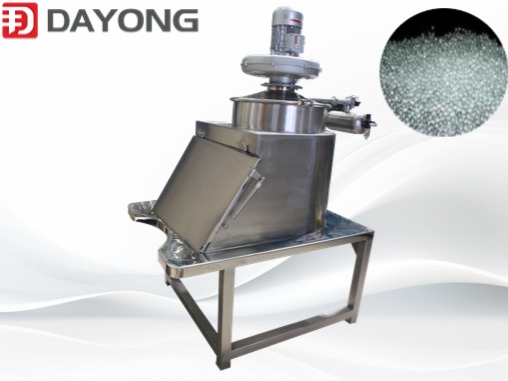

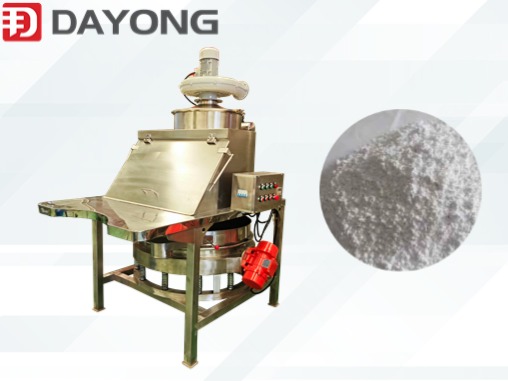

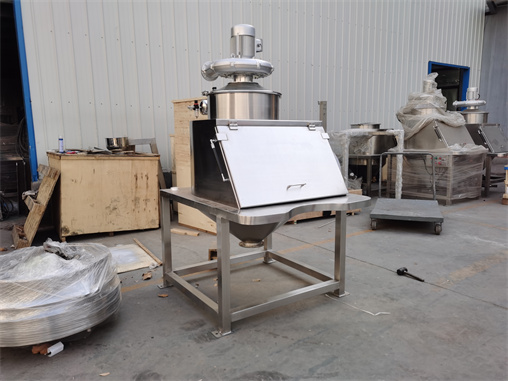

Dust Free Feed Station Manufacturer

The dust-free feeding station can handle the unpacking, unloading and transportation of powder, granular and small ton bags. In addition, it is widely used in petrochemical, API, plastic, carbon black, mining, food additives, cement and other industries. It has simple structure, low production cost, simple and convenient operation, high cost performance, and its own dust collection, so that the dust will not fly any more.

Closed bag opening, no flying dust, improved working environment and reduced production cost. Applicable conditions: large bag packaging materials for powder and granular materials.

The dust-free feeding station is mainly used to manually remove the belt and pour the materials into the equipment of the dust-free feeding station. The negative pressure dust collection device is used to automatically pump the dust particles generated in the process of unloading, avoiding the dust flying in the traditional feeding method. When the small bag materials need to be unpacked and poured into the next process, only manual unpacking is required and then they are put into the dust-free feeding station system. The material dust generated during feeding is collected by the dust collection fan. The material can intercept large pieces of material and foreign matters through the safety screen, so as to ensure that the qualified particles are discharged. The dust-free feeding station system is applicable to the feeding, screening and unloading of small bags in the new energy lithium battery, chemical industry, food and other industries, especially for the feeding and screening of materials with poor fluidity. Due to the role of the dust collecting fan during unpacking, the material dust can be avoided flying everywhere. The equipment can be used for a variety of production processes, either as a single powder feeding and unloading equipment, or as an important powder unloading in powder conveying systems such as one point multi feeding and multi-point feeding.