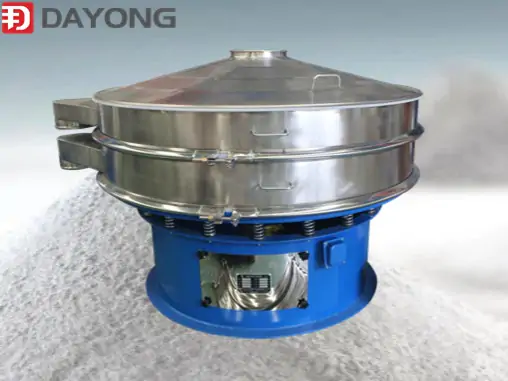

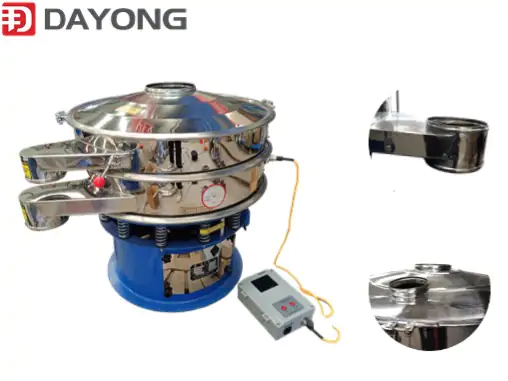

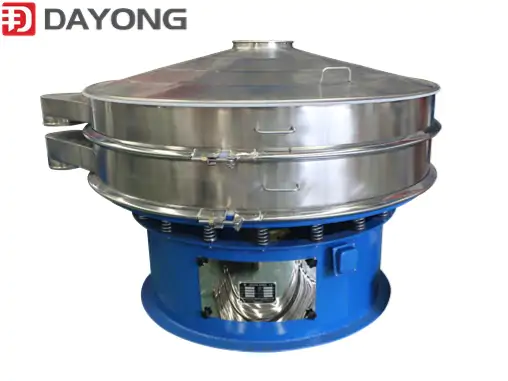

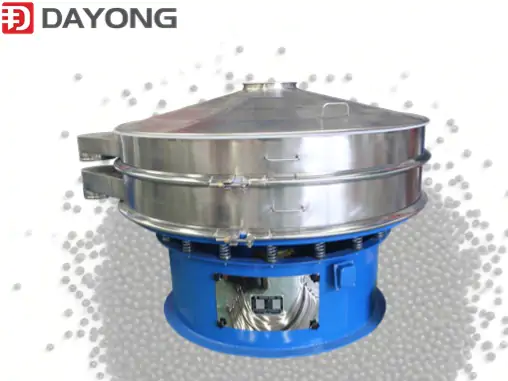

Customers Trust Low Maintenance Cost Pigment Rotary Vibrating Sieve Machine

The customers of Xinxiang Dayong company believe that the pigment rotary vibrating screen with low maintenance cost is specially used for pigment screening in the chemical industry.The main part is stainless steel, and the base can be carbon steel or stainless steel.Compact structure, little dust, low noise and low energy consumption.

DY-1200 Vibrating Screen

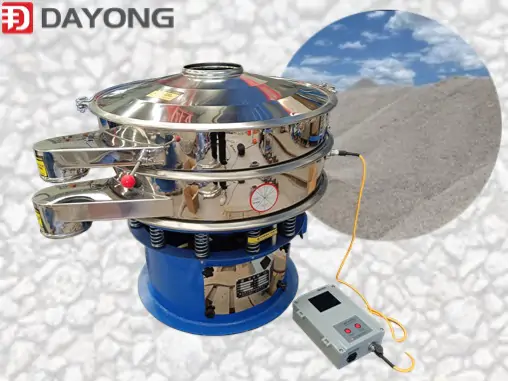

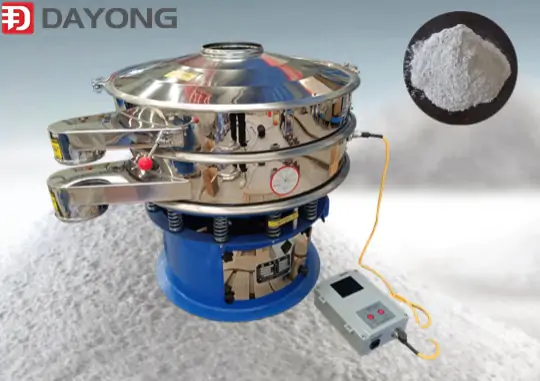

Customers believe that the pigment rotary vibrating screen with low maintenance cost is a high-precision fine powder screening machine with low noise and high efficiency. https://www.alibaba.com/product-detail/Vibrating-Sieve-Dayong-Powder-Vibration-Shaker_1600246386762.html?spm=a2700.galleryofferlist.normal_offer.d_title.1be46ce6c5gIQC&s=pThe upper and lower ends of the motor are equipped with eccentric blocks to convert the rotating motion of the motor into horizontal, vertical and inclined three-dimensional motion, and then transfer the motion to the powder on the screen surface. The trajectory of the powder on the screen surface can be changed by adjusting the phase angle at the upper and lower ends. It takes 3-5 minutes to quickly change the screen. Fully enclosed, suitable for screening and filtration of particles, powder and mucus. The vibrating screen is composed of a vertical motor as the excitation source.Metallurgy and mining industry: quartz sand, barite powder, ore, titanium oxide, zinc oxide, etc.