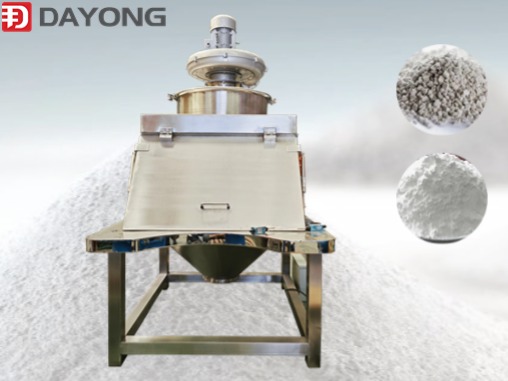

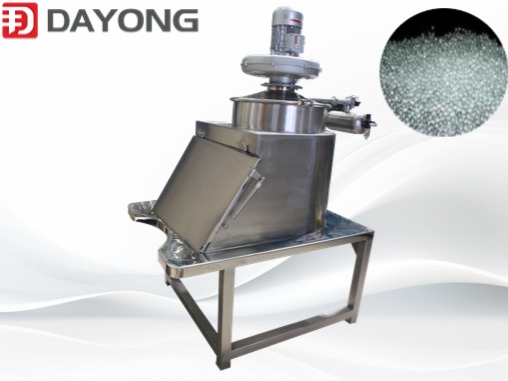

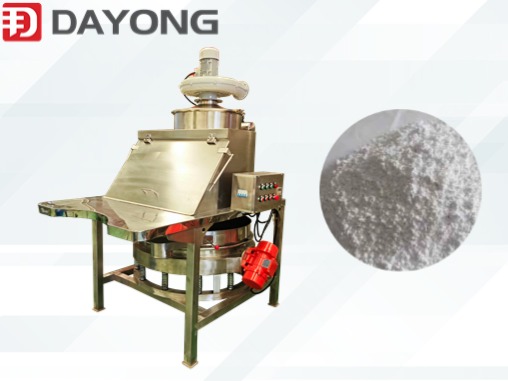

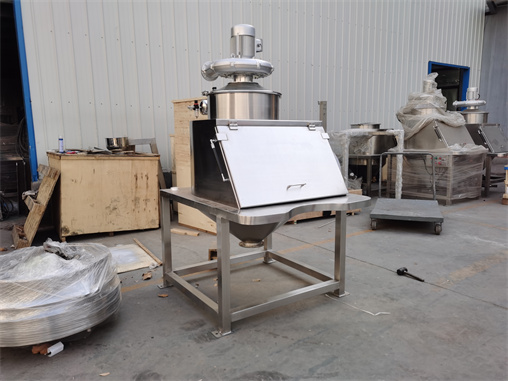

Custom Dust-Free Feeding Station for Flour Factories

Dust during flour feeding wastes materials and harms workers. A company solved this by using custom dust-free feeding stations (2.1m and 1.9m) from Xinxiang Dayong. The closed design with a strong filter reduces dust, improves safety, and increases efficiency by 30%. Made of food-safe stainless steel, it connects to other machines for fully enclosed handling. Contact us for more details!

In flour factories, dust during the feeding process has been a big problem. The old way of feeding flour creates a lot of dust, which not only wastes flour but also harms workers’ health. A flour company solved this problem by ordering special dust-free feeding stations from Xinxiang Dayong Vibration Equipment Co., Ltd. These stations come in two sizes: 2.1 meters and 1.9 meters tall.

The dust-free feeder is designed to be closed and has a strong filter system. This keeps the dust inside the machine and stops it from spreading. The two sizes were made to fit the factory’s needs perfectly. After using the new equipment, the factory saw less dust in the air, used 15% less flour, and made the workplace much safer for workers. The feeding process also became 30% faster, saving the company money. The machine is made of food-safe stainless steel, so it meets all safety standards.

Xinxiang Dayong Vibration Equipment Co., Ltd. also offers a flexible design that can connect to other machines like vibrating screens or conveyors, making the whole process dust-free. If you have any questions, feel free to ask us!