Classification And Selection Of High-efficiency Vibrating Screens

There are several types of circular vibrating screens, such as three-dimensional vibrating screens, ultrasonic vibrating screens, and in-line vibrating screens.

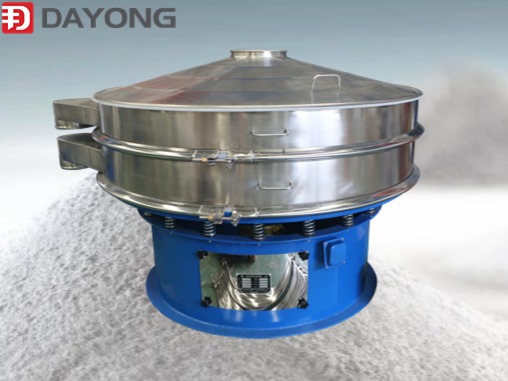

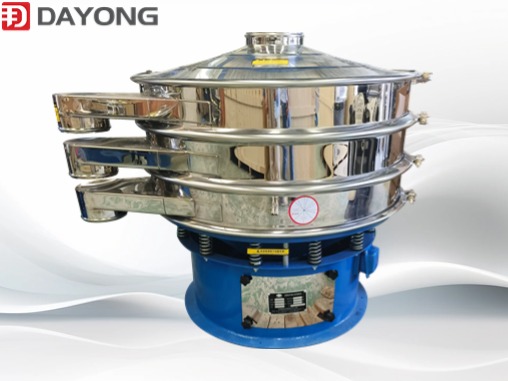

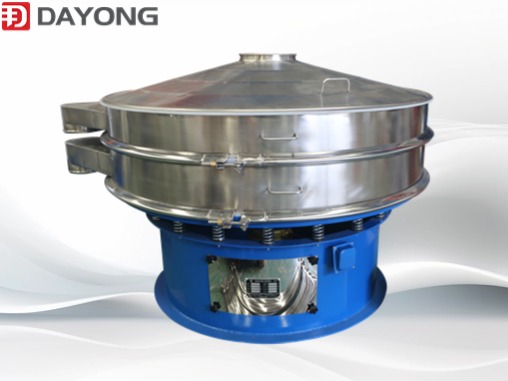

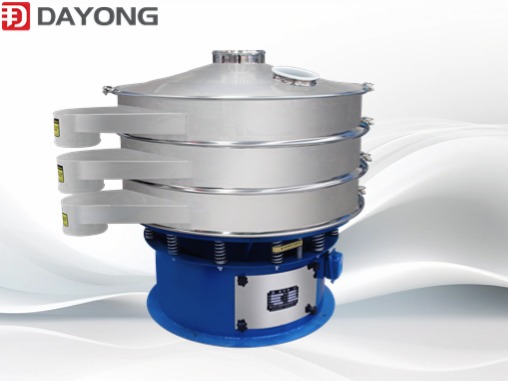

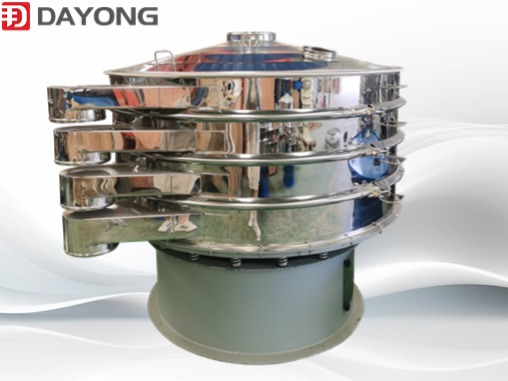

This article mainly describes the classification and selection of vibrating screening machines, and the narration of professionals from Dayong Vibration Equipment Company.The three-dimensional vibrating screen changes the movement trajectory of the material on the screen surface by changing the phase angle of the upper and lower weights. It is generally suitable for the screening of various particles and powders, as well as the filtration of slurry. There are several screen cleaning devices that can reduce the chance of blocking the screen.

I hope this article can help you. If you have related questions, you can contact us. Dayong Vibration Equipment Co., Ltd. specializes in the production of screening and conveying machinery. With mature technology, professionals will give you the best solution.

There are several types of circular vibrating screens, such as three-dimensional vibrating screens, ultrasonic vibrating screens, and in-line vibrating screens.

The three-dimensional vibrating screen changes the movement trajectory of the material on the screen surface by changing the phase angle of the upper and lower weights. It is generally suitable for the screening of various particles and powders, as well as the filtration of slurry. There are several screen cleaning devices that can reduce the chance of blocking the screen.

In-line sieves are usually used in dry powder and flour manufacturing, so they are also called flour sifters, which are used for direct impurity removal and discharge.

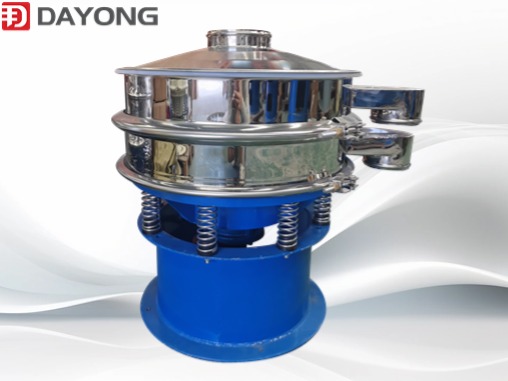

The ultrasonic vibrating sieve is based on the rotary vibrating screen and adds a set of ultrasonic system device, which realizes the combination of ultrasonic wave and vibrating screen, which can effectively solve the agglomeration, static electricity, and adsorption materials of powder particles in the screening process. Sifting problems.

Selection of vibration screening machine:

1. Screening purpose: a. Fine screening: rotary vibrating screen, ultrasonic vibrating screen, airflow screen, etc.

b. Rough screening: linear vibrating screen, mining vibrating screen, straight row screen, etc.

2. Screening material properties: density, shape, temperature, viscosity, particle size, activity, particle size distribution, whether it is corrosive.

3. Processing capacity: the ability to process the size of the material per unit time. When the screen load is large, the screening efficiency is low.

4. Working environment: site closure, dry humidity, safety, and pollution requirements.

5. Judgment of materials: net pass rate, specific gravity, processing capacity, whether the shape is specification, viscosity, moisture content.

I hope this article can help you. If you have related questions, you can contact us. Dayong Vibration Equipment Co., Ltd. specializes in the production of screening and conveying machinery. With mature technology, professionals will give you the best solution.