Chinese Competitive Price Explosion-proof Large Capacity Vibrating Screen Separator Machine

Dayong Vibration Equipment Company specializes in customizing screening and conveying machinery and other equipment, and has established good cooperative relations with domestic and foreign customers for a long time. The technology is mature and can meet your diverse needs.

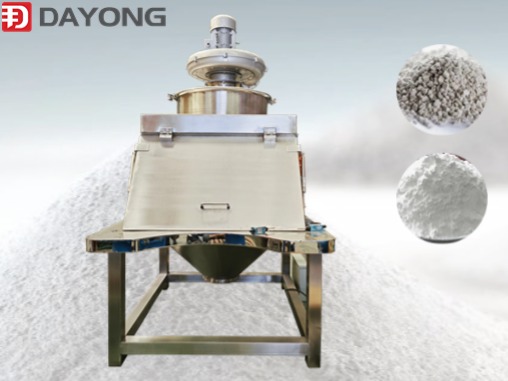

The dedicated vertical vibration motor is the excitation source, without mechanical transmission, with high energy efficiency, easy adjustment, reliable quality and high stability.

High screening accuracy and high efficiency, suitable for screening and filtering various powders, granules, mucus and other materials.

The design is exquisite and durable, with low noise, continuous operation, and the material can be automatically discharged in 360-degree direction.

The rotary vibrating screen produced and sold by Xinxiang Dayong Vibration Equipment Co., Ltd. can be used for fine screening. Powder vibrating screen machines are specially designed for precise sorting or grading. Fine screening equipment, our goal is to solve all screening problems. Our rocking screen solves the work problems that ordinary vibrating screens cannot solve for you. The screen height can reach 5 layers, and it can separate six kinds of materials at the same time, with lower noise and longer service life of the screen.

Ultrasonic vibration sieving machine, the particle size classification of dry powder can reach 25μm or liquid filtration can reach 10μm. Ultrasonic screening and cleaning system can be combined with various types of circular vibrating screening machines, so that the screen is subjected to low-frequency vibration and superimposed high-frequency ultrasonic vibration, so that large particles on the screen are suspended, thus avoiding clogging of mesh holes and solving strong problems. Adsorption, easy to agglomerate, static electricity, screening problems of light specific gravity materials. It has been successfully used in silicon carbide (325-500 mesh), electromagnetic powder, negative electrode material, laser powder, carbon powder, powder coating, alloy powder, molybdenum powder, stainless steel powder, tungsten powder, cobalt powder, nickel powder, quartz powder, malt powder Screening of powder, spore powder, etc. Its superior performance and structural form have been in line with international standards and have been well received by customers.