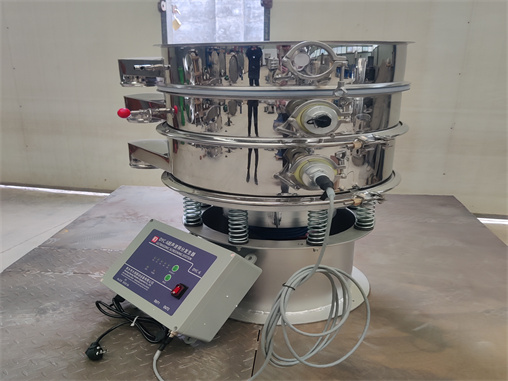

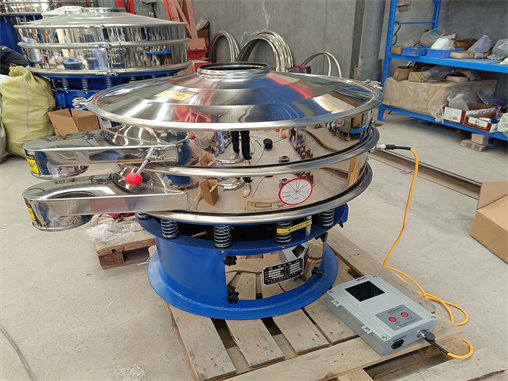

Chemical Powder Ultrasonic Rotary Sieve Machine

The hot -selling vibration sieve sold by Xinxiang Dayong Company is small, saving space, light weight, and convenient movement. The exit direction can be changed at will. According to the needs of the mechanical structure and process parameters, the vibrator is located at the top of the center of gravity of the sieve box. This layout makes the sieve machine on the ellipse trajectory, the outlet is still ellipse. Do the reverse self -rotation to achieve the purpose of screening such as flour and other materials.

Rotary vibrating screen classification

According to the different design of the vibrating body of the rotary vibrating screen, it is divided into:

A. Standard rotary vibrating screen: suitable for screening various dry and wet materials.

B. Strong vibration high-efficiency vibrating screen: The strong vibration type rotary vibrating screen is 2-4 times the vibration acceleration of the standard type rotary vibrating screen. In the process of screening materials, the output can be guaranteed to be 2-4 times that of the same type.

According to the specific needs of screening materials, the vibrating screen can be divided into one-layer, two-layer, three-layer and four-layer type rotary screen. According to the different needs of users, it can be divided into standard rotary vibrating screen, ultrasonic vibrating screen, edged rotary vibrating screen, gate type rotary vibrating screen, etc. The materials are mostly stainless steel and carbon steel. According to the different applicable industries, it can be divided into flour screen, powder metallurgy vibrating screen, medicine vibrating screen and so on.