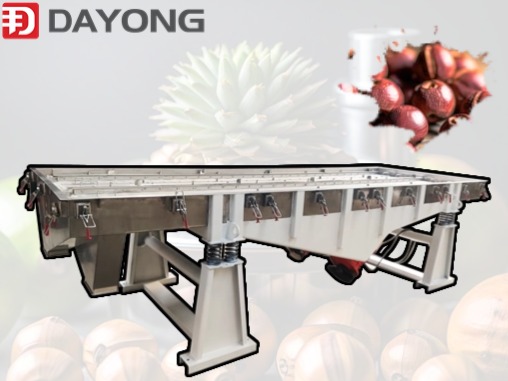

Carbon Steel Or stainless Steel Linear Perlite Vibrating Screens Sifter Machine /Small Linear Vibrating Screen

Xinxiang Dayong company has focused on the manufacturing of screening and conveying equipment for 11 years. The Carbon Steel Or stainless Steel Linear Perlite Vibrating Screens Sifter Machine /Small Linear Vibrating Screen produced and sold by Xinxiang Dayong company has a wide range of applications and is Carbon Steel Or stainless Steel Linear Perlite Vibrating Screens Sifter Machine /Small Linear Vibrating Screenspecially used for screening perlite.It is suitable for particle sieving, classification, impurity removal and filtration, with large processing capacity.Simple structure, tight sealing, low noise, convenient maintenance and low energy consumption.

DZSF515,DZSF520,DZSF525,DZSF1020, DZSF1025 ,DZSF1030

Price:$1000-$1500

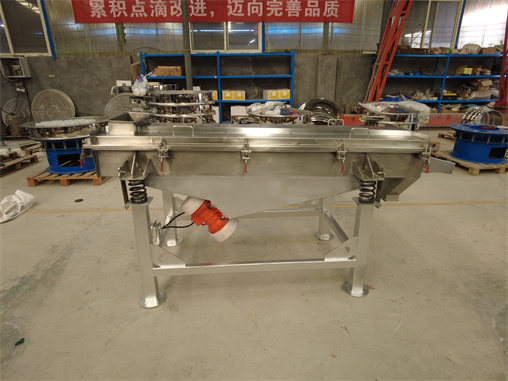

Carbon Steel Or stainless Steel Linear Perlite Vibrating Screens Sifter Machine /Small Linear Vibrating Screen is a standard and universal screening equipment. The motion track of the screen box is close to a straight line. Almost all linear vibrating screens are composed of screen box, support or suspension device, transmission device, vibration isolation device, etc. The linear vibrating screen adopts a vibration source and is excited by a vibration motor to make the screen material throw up and move forward in a straight line. A plurality of balls at the bottom of the screen frame collide with each other during vibration, which can effectively clean the screen and avoid blockage.When the equipment is shut down, there will be an instantaneous resonance area. At this time, the amplitude and noise will increase significantly, which is a normal phenomenon. Before the equipment starts and stops, there should be no remaining material on the screen surface. The screen should be checked frequently for tension and damage. If it is damaged, it should be replaced immediately.This product is widely used in the screening of dry powder or granular materials in chemical, food, plastic, medicine, metallurgy, glass, building materials, grain, fertilizer, abrasive, ceramics and other industries. The particle size of the material is 0.074-5mm, the water content is less than 7%, and the sieving of various dry powder or granular materials without stickiness, the feeding particle size is not more than 10mm.