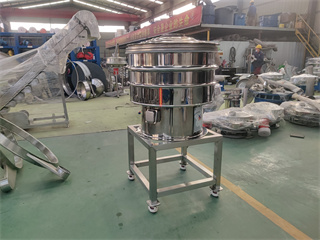

Automatic Rotary Stainless Steel Flour Vibrator Sieve /Tea powder Screening Machine/flour sieve/flour sifter machine/food grade pollen screen

Automatic Rotary Stainless Steel Flour Vibrator Sieve /Tea powder Screening Machine/flour sieve/flour sifter machine/food grade pollen screen produced and sold by Xinxiang Dayong Vibrating Equipment Co., Ltd. is specially used to screen flour, tea powder and food grade pollen.It only takes 3 to 5 minutes to replace the screen of the corresponding size. In order to improve the screening effect of the rotating vibrating screen when screening fine materials, an ultrasonic system and other equipment can be added.

DY-600 Vibrating Screen /DY-800 Vibrating Screen/DY-1000 Vibrating Screen

Price:598$-898$

Automatic Rotary Stainless Steel Flour Vibrator Sieve /Tea powder Screening Machine/flour sieve/flour sifter machine/food grade pollen screen is a high-precision screening machine. The rotating filter screen is composed of a vertical motor, with eccentric blocks installed at both ends. We can produce horizontal, vertical, and inclined movements by adjusting the up and down eccentric weights. The diameter can vary from 600 mm to 2000 mm, and it can be used in single or multiple layers. The materials can be divided into full carton steel, contact stainless steel and full stainless steel, which can be selected according to the screening of the material.The grid of the rotating vibrating screen will not be blocked, it can be screened to 500 mesh or 0.028mm, and the coarse and waste materials can be discharged automatically. Can work continuously.In order to further improve your material throughput, we offer optional unclogging systems that will “unclog” the sieve as it is used.

We offer two main cleaning techniques that have proven their effectiveness and robustness:

Ball cleaning: a system for cleaning the lower part of the screen cloth consisting of elastomer balls that bounce off a perforated stainless steel plate. This system is especially recommended in the event of the presence of fine products that can stick to the fabric threads.

Brush cleaning: a system where the brushes are located on the fabric. It is effective in certain very specific cases, such as when particularly sticky products or products that tend to clump together are used. This system is placed directly on the sieve and the rotation of the brushes is carried out thanks to the three-dimensional movements of the sifter.