Application of Direct Screening in Positive Electrode Material Screening

The direct discharge screening of positive electrode materials can improve the purity and consistency of the materials. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction to the advantages of direct discharge screens.

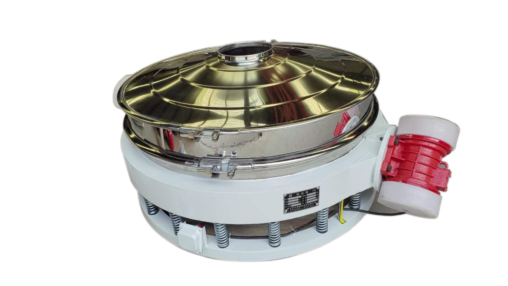

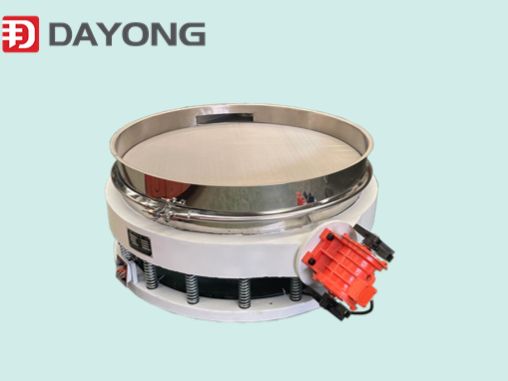

Screening is a crucial step in the production process of positive electrode materials for lithium batteries. In order to ensure the purity and consistency of the positive electrode material, a lithium battery production enterprise purchased a one meter diameter direct discharge sieve from Xinxiang Dayong Vibration Equipment Co., Ltd. for screening operations. The output of this equipment is about one ton per hour.

Equipment advantages:

1.The straight screening adopts internal polishing treatment technology. It can reduce the accumulation of materials during the screening process. This can avoid the formation of difficult to clean dead corners. This not only improves screening efficiency, but also ensures screening quality.

2.The material screened by the direct discharge vibrating sieve can be quickly and directly discharged from directly below the sieve machine. This avoids the problems of blockage and material accumulation that may occur during traditional screening processes.

3.Low-Profile separator has excellent screening efficiency and precision. Through precise screen design and optimized vibration parameters, it can effectively separate impurities and foreign objects from materials.

4.Direct discharge screen also has the advantages of energy conservation, environmental protection, and easy maintenance.

Direct screening has demonstrated significant advantages and application value in the screening of positive electrode materials. Xinxiang Dayong Vibration Equipment Co., Ltd. is a professional screening equipment manufacturer. Welcome to consult!