Application and advantages of direct discharge sieve

Direct discharge screening is widely used in industries such as chemical, food, and pharmaceutical, for material screening, grading, and impurity removal. Its advantages lie in efficient and high-precision screening, easy maintenance and cleaning, compact structure, and convenient operation.

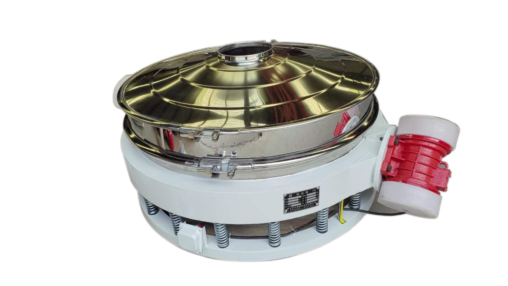

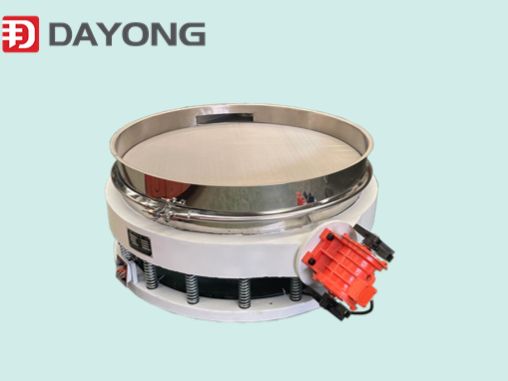

Direct discharge screen is a widely used screening equipment in the industrial field. Its unique design plays an important role in the screening, grading, and impurity removal processes of various materials. Xinxiang Dayong Vibration Machinery Co., Ltd. will provide you with a detailed explanation.

The application range of direct discharge sieve is wide, covering multiple industries such as food, mining, ceramics, etc. For example, in the food industry, it is commonly used for screening and grading food raw materials. This ensures the quality and safety of the product.

The advantages of Low-Profile separator are mainly reflected in high screening efficiency, high screening accuracy, easy maintenance and cleaning. Its efficient screening method can complete a large number of screening operations in a short period of time, improving production efficiency. Meanwhile, high-precision screening technology can achieve precise classification of granular materials without worrying about mixing particles of similar sizes. In addition, the straight discharge sieve has a compact structure, low overall height, and is easy to install and layout. And the operation is simple and convenient, with good maintenance performance.

In short, the direct discharge sieve has become a leader in screening equipment with its wide range of applications and many advantages, providing efficient and reliable solutions for material screening in various industries. If you have any questions, please feel free to consult Xinxiang Dayong Vibration Equipment Co., Ltd!