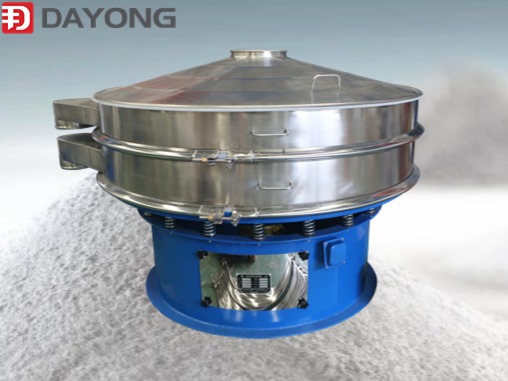

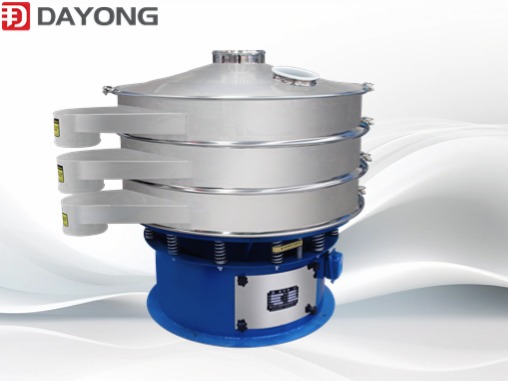

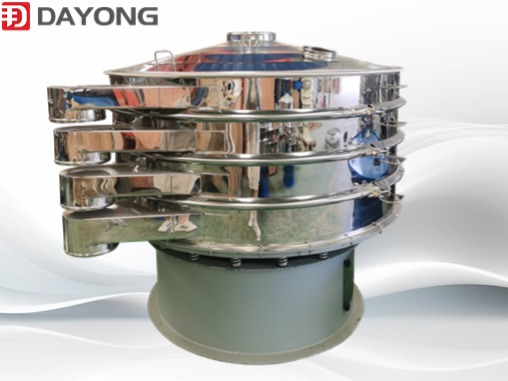

Analysis And Summary Of The Damage Of The Vibrating Screen Mesh/Vibratory Screening Separator

Usually, the reasons for the abnormal damage of the vibrating screen can be summarized as: the quality of the screen, the installation of the screen, the reason of the vibration motor, the reason of the clay accumulation, etc. This article mainly analyzes these reasons.

The abnormal damage of the vibrating screen not only increases the production cost, but also reduces the production efficiency. Therefore, the correct use of the vibrating screen and the screen is particularly important. The engineers of Dayong Vibration Equipment Co., Ltd. analyzed the abnormal damage of the vibrating screen. The reasons and detailed solutions can help customers solve the problem. If you have any questions about the product, you can contact us, and our technicians will give you the best solution.

Usually, the reasons for the abnormal damage of the vibrating screen can be summarized as: the quality of the screen, the installation of the screen, the reason of the vibration motor, the reason of the clay accumulation, etc. The following will analyze these reasons one by one:

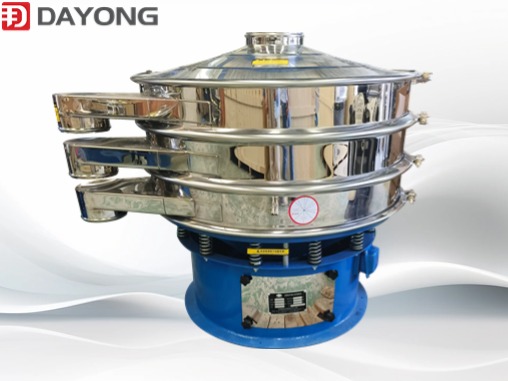

1. Reasons for screen quality

The screen of the vibrating screen is usually composed of two parts: the screen layer and the force layer. The two layers are required to be closely combined. If the pre-tensioning process of the screen is poor, when the force layer at the bottom of the screen is tightened, the screen layer is not stretched. tight, causing premature damage to the screen;

Solution: Buy a screen with good quality and excellent technology.

2. Reasons for screen installation

When installing the screen, the basic requirements for screen installation are not met. For example, the tension of the screen is not enough, causing the screen to vibrate, resulting in breakage or damage along the edge of the screen or the edge of the bead;

Solution: Strictly follow the instructions when installing the screen.

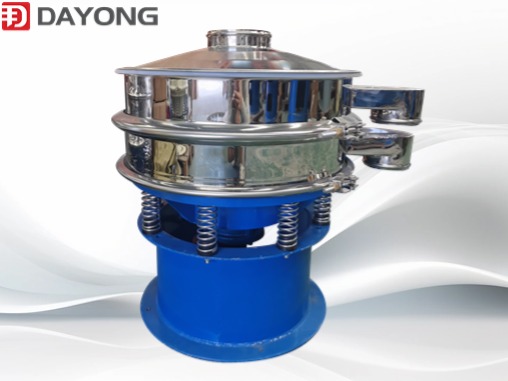

3. Reasons for vibration motor

When debugging the vibrating motor, some users think that the drill cuttings can move forward based on the experience of using the linear vibrating screen or the uniaxial vibrating screen, but this experience is not applicable to the translational elliptical vibrating screen. There is a force to roll backwards, and the forward speed of the drill cuttings will be much slower than normal, causing the material to stay on the screen for too long, and even unable to remove the drill cuttings, resulting in premature damage to the screen;

Solution:

①. When the screen box is running, press the stop button of the electric control box, and the vibrating screen will slowly stop at this time. Observe the elliptical trajectory formed by the small points on the side panel when the vibrating screen is running, and roll to the sand outlet to make the correct turn. ;

②. Remove the shield of the vibrator and check whether the eccentric blocks rotate outwards;

③. Replace any 2 phase wires in the incoming power supply of the electric control box, sprinkle some sand on the screen, the one with the faster sand discharge is the correct direction.

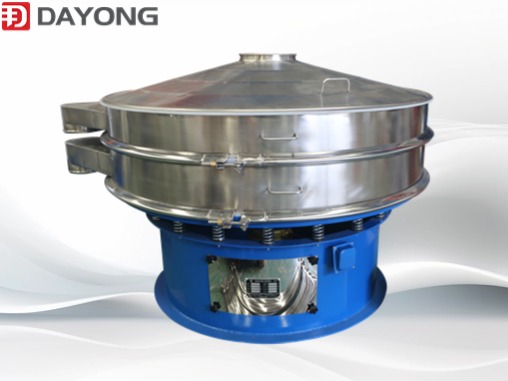

4. Causes of clay accumulation

In the case of clay accumulation, the vibration amplitude of the equipment is too small, it is difficult to screen under the condition of polymer drilling fluid, and the viscous force of drill cuttings (clay) cannot be effectively overcome, resulting in the accumulation of drill cuttings on the screen and rapid damage to the screen. network;

Solution:

①. Increase the vibration amplitude;

②. Rinse the screen and drill cuttings with sprayed water to reduce the viscosity of the drill cuttings, but this method is only suitable for occasions where water is allowed to be added;

③. Adjust the angle of the screen at the end of the sand discharge port downward, which is conducive to the discharge of cuttings by gravity, but may lead to slurry running;

④. Replace the mesh of the screen or adjust the flow rate of the single screen to ensure that the flow dead point of the drilling fluid is close to the screen outlet, so that the drilling cuttings can be smoothly discharged under the lubrication of the drilling fluid.

The abnormal damage of the vibrating sieve not only increases the production cost, but also reduces the production efficiency. Therefore, the correct use of the vibrating screen and the screen is particularly important. The engineers of Dayong Vibration Equipment Co., Ltd. analyzed the abnormal damage of the vibrating screen. The reasons and detailed solutions can help customers solve the problem. If you have any questions about the product, you can contact us, and our technicians will give you the best solution.