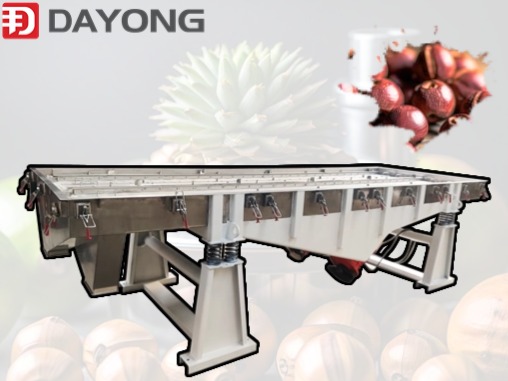

Aluminum Powder Linear Vibrator Screen Machine/Ferrous Powder Vibrating Screen Machines For Sale

Xinxiang Dayong company has focused on the manufacturing of screening and conveying equipment for 11 years. The aluminum powder linear vibrating screen machine / iron powder vibrating screen machine produced and sold by Xinxiang Dayong company is sold. It has a wide range of applications and is dedicated to screening iron powder.Bouncing ball cleaning: Food-grade rubber and silicone balls bounce on the punching plate under the screen, bouncing against the metal mesh to reduce mesh blockage. This system is simple to use, easy to maintain and suitable for most granular materials.

DZSF515,DZSF520,DZSF525,DZSF1020, DZSF1025 ,DZSF1030

Price:$1000-$1500

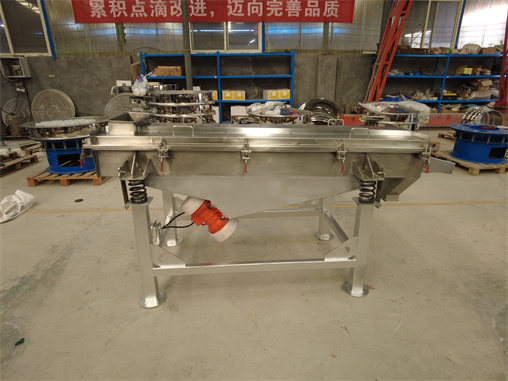

When the Aluminum Powder Linear Vibrator Screen Machine/Ferrous Powder Vibrating Screen Machines For Sale , the two motors rotate in the opposite direction synchronously, so that the exciter generates a reverse exciting force, which forces the screen box to drive the screen to do longitudinal movement, so that the material on it is periodically thrown forward by the exciting force for a range. In this way, the material screening operation is completed. When the two vibration motors are rotated synchronously and in opposite directions, the exciting force generated by the eccentric blocks cancels each other in the direction parallel to the motor axis, and superimposes a resultant force in the direction perpendicular to the motor axis. Therefore, the motion trajectory of the screen machine is a straight line. The two motor shafts have an inclination angle in the vertical direction relative to the screen surface. Under the combined force of the exciting force and the self-gravity of the material, the material is thrown on the screen surface to jump or move forward in a straight line, so as to achieve the purpose of screening and grading the material. Linear vibrating screen, also known as light linear screen, is used for the screening of powdery or granular dry materials or the filtration of liquid materials. The finer screening can reach 325 mesh/inch. The vibration source with adjustable angle can be used in single layer or layer according to customer’s screening and filtering requirements, and it can reach five layers. The screen frame is generally made of wood. When screening corrosive materials, the parts in contact with the materials can be made of stainless steel.