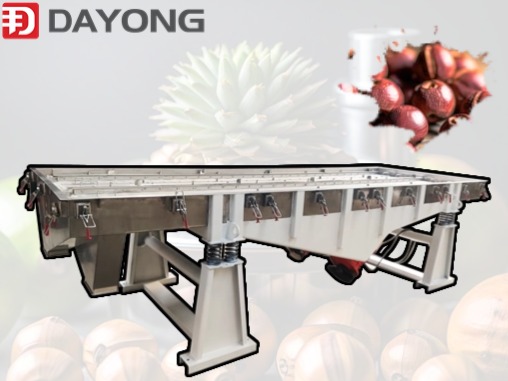

Almond Sieving Machine/Tobacco Sieving Machine/Dry Herb Sieve Machine /Fertilizer Size Sieves Machine/Octagonal Sieve Machine

Almond Sieving Machine/Tobacco Sieving Machine/Dry Herb Sieve Machine /Fertilizer Size Sieves Machine/Octagonal Sieve Machine produced and sold by Xinxiang Dayong vibration equipment Co., Ltd. is specially used to screen octagonal / dry vanilla almond cut tobacco.Vibration damping spring: prevent the vibration from being transmitted to the ground and support the full weight of the screen box. When installing, the spring must be perpendicular to the ground.

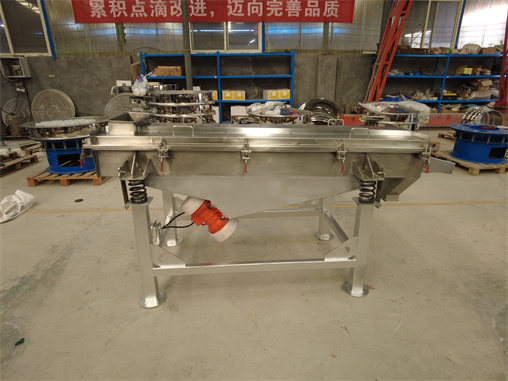

Material: stainless steel, carbon steel

Model: DZSF515, DZSF520, DZSF525, DZSF1020, DZSF1025, DZSF1030

Price: $1000-$1500

When the two Almond Sieving Machine/Tobacco Sieving Machine/Dry Herb Sieve Machine /Fertilizer Size Sieves Machine/Octagonal Sieve Machine motors vertically installed on the screen rotate relative to each other, the eccentric blocks of the two vibration motors generate rated exciting force. The horizontal exciting force cancels each other out, and the vertical exciting force is transmitted to the entire screen surface through the vibration of the body. Due to the action of the vertical exciting force, the material jumps on the screen surface towards the discharge port. The material smaller than the screen will fall into the lower layer after jumping and be discharged from the outlet. Due to the reasonable screening method, after passing through the vibrating screen, materials with different concentrations and different particle sizes can be obtained, and the materials can be classified.Bracket: It consists of four pillars and two channel steels, which support the screen box. When installing, the pillars must be perpendicular to the ground, and the channel steels below the two pillars should be parallel to each other.

Linear vibrating screen is commonly used in: ferrosilicon, sand, pepper particles, wheat peel, pumpkin seeds, silicon powder, sugar, traditional Chinese medicine, betel nut, silicon carbide powder, stone, activated carbon particles, soil, sand, millet, pulp, shells, cooked Sesame, machine-made sand, chrysanthemum, quartz sand, construction waste, coke powder, plastic particles, river sand and other materials Installation, commissioning and use of linear vibrating screen:

The equipment should be fixed on a special foundation and fixed by embedded bolts. If no special foundation is laid, an anti-vibration rubber sheet should be laid between the workbench and the equipment base, and a safe and reliable grounding protection line must be provided for the equipment before use.