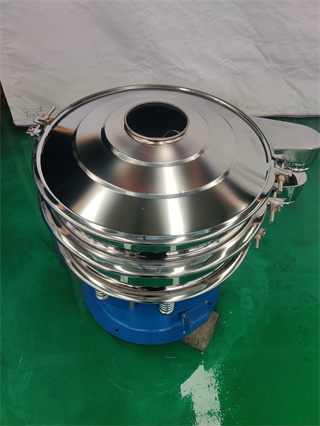

1200 Mm Rotary Vibration Screen/grain Vibration Screening /mobile Vibration Screen

The structure of the vibrating screen professionally produced by Dayong Company: vibrating motor, base, middle frame of vibrating screen, dust cover, spring, mesh frame and other components form a complete vibrating screen that can be screened, classified and filtered, ultrasonic vibrating screen, Linear vibrating screen, mining vibrating screen, etc. to meet the diverse needs of customers

The low-frequency motion of the material on the screen and the ultrasonic wave can improve the screening efficiency and quality.

The design of ultrasonic vibrating screen is designed and developed for different material screening, such as density, particle, liquid, etc.

Ultrasonic vibrating screen changes the pollution and wear caused by conventional screening methods to materials, and reduces noise.

The screening accuracy of ultrasonic vibrating screen can be increased by more than 80%, and the output can be increased by 2 to 5 times.

The ultrasonic vibrating screen maintains the mesh size, stabilizes the screening accuracy, and reduces the number of repeated screenings.

The combination of ultrasonic wave and vibrating screen solves the problem that the material has strong adsorption and is difficult to screen.

Ultrasonic screening system consists of ultrasonic resonance power supply, oscillator, outer mesh ring and resonance ring

Ultrasonic vibrating screen solves screening problems such as strong adsorption, easy agglomeration and high static electricity.

Ultrasonic vibrating screen solves the screening problems of high precision, high density and light specific gravity.

Ultrasonic vibrating screen has the characteristics of stable screening accuracy, high efficiency and high output. Welcome to buy.